Technologies for commercialisation

Technologies for commercialisation

Brief Description : Bullock Operated Sprayer can be used for spraying of insecticides, pesticides and weedicides on vegetables, row crops and soil. Is operated by two bullocks and loaded on the cart. No fuel is required. Height of the sprayer nozzles can be adjusted as per the requirement. The width of implement is 6 meters (14 nozzles, spacing between the nozzles adjustable). The equipment reduces labor requirement and cost of operation.

Cost of Implement : 55,000/-

Beneficiaries /End User : Rural entrepreneurs/ farmers

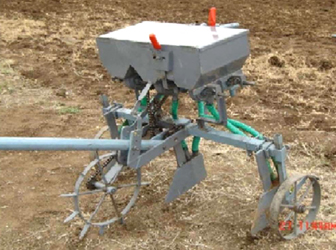

Brief Description : Suitable for planting soybean, Gram, Pegion pea, wheat, Groundnut crops Helps in timely operation with reduction in labor requirement

Cost of Implement : 9,400/-

End User : Village entrepreneur, Small and Marginal Farmers

Brief Description : The newly developed earth auger for making pits of uniform dimensions. It is easy and comfortably can be operated by single Operator. It can make holes up to 1 meter depth of diameter (9', 10', 11'). The pit making bits can be exchanged. Single operator (Man/Women) petrol operated engine of capacity 1.5/3.5 HP. It has foldable frame with material carrier facility. Capacity is minimum 50pits/hr.

Cost of operation Rs.21-30/- per pit.

Beneficiaries and End User :

Entrepreneurs /rural craftsman/Farmer

Approximate Cost : Rs.45,000

Beneficiaries and End User :

Entrepreneurs /rural craftsman/Women Farmer

Approximate Cost : Type-II Rs. 54,000/-

Brief Description : The small manually operated boom sprayer is designed for small and marginal farmers. The technical description of MMBS device is as follows

The results obtained and recorded after field testing was as follows

Approximate Cost : 4,500/-

Beneficiaries /End User : Small and Marginal Farmer

Brief Description : The newly developed Sprayer can be used for spraying pesticides, fungicides, fertilizer etc. It is self-sufficient because it contains own power source and works without noise & vibrations. Operator feels comfort in high temp sunlight due to solar panel's shed on head portion. It is operated by using dual power such as solar energy or battery system which helps to operate in cloudy atmosphere. The Battery is also useful for lightning in night hours. It is suitable to spray all kinds of crops from 2.5 ft. to 8.0 ft. height. The discharge of sprayer was observed between 2.5 lpm to 3.0 lpm which depends on solar radiation. The field capacity of solar sprayer is 0.15 Ha/hr.

Approximate Cost : 13,000/-

Beneficiaries /End User : Entrepreneurs /Rural craftsman/Farmer

Brief Description : Following are the technical features with description.

Cost of Implement : 21,000/-

Beneficiaries /End User : Entrepreneurs /rural craftsman/Farmer

Brief Description : Among different kind of soy products, soymilk has gained much popularity as an excellent source of high-quality protein which is commonly recommended as a less-expensive source substitute for cow's milk. Fresh soyamilk has a very short shelf life which consequently limits its consumption to areas close to the production site. The soymilk produced at room temperature has limited shelf life of less than 24 hr. The industrial interest has led extensive research concerning shelf life and organoleptic quality of soymilk during storage. During storage period of soymilk microbiological, physicochemical, and sensory properties change greatly thereby causing spoilage. Microbiological safety has become a common need not only due to consumers claim for healthy food but also due to the recent changes in soymilk production and storage conditions. Soymilk packed in sterilized glass bottles and again sterilized for 121° for 20 minutes improve the shelf life of soymilk stored at refrigerated condition upto 170 days and could be stored at refrigerated condition upto 170 days and at ambient condition upto 90 days.

Beneficiaries /End User : New upcoming entrepreneurs, Self-help groups, Farmers

Approximate Costing

Brief Description : Shelf life of soypaneer is 6 hrs at ambient condition. Storage of soypaneer at low temperature is essential, while transporting the product for a long distance in a suitable packaging material to maintain quality. The vendors keep soypaneer for sale at room temperature. Hence, it is also necessary to evaluate the shelf life of product at ambient temperature. Vacuum packaging is one of the easiest, most efficient and economical process of preserving quality and improving shelf life of soypaneer. Vacuum packaging with LDPE 200 gauge is recommended to enhance the shelf life of soypaneer upto 10 days at refrigerated condition (± 5°).

Beneficiaries /End User : New upcoming entrepreneurs, Self-help groups, Farmers

Approximate Costing

Brief Description : Roasted soy nuts are whole mature soybeans that have been soaked in water and then baked until browned. They are very suitable snack item being popularized all over India. Soy nuts are a nutrition powerhouse and offer many health benefits. They are very rich in protein, fiber, healthy fats, minerals and vitamins. The net effect of roasting techniques is the removal of anti nutrients and increase the nutritive value and overall acceptance. The existing roasting equipment is not suitable for roasting of soybean, so roaster based on HTST principle for preparation of soy nut has been developed. The developed roaster may be useful for roasting multi grains. The electrically operated (2000 Watt) roaster has capacity of 2 kg/batch. The machine is having overall dimensions of 510.25 mm (l) x 510.25 mm (b) x 210.25 mm (h). The optimized soaking time roasting temperature and roasting time for preparation of soy nut in the developed roaster is 60 min, 130° and 2.5 min respectively. The cost of the unit is Rs.25000/-. The developed roaster is suitable for production of soy nut.

Beneficiaries /End User : New upcoming entrepreneurs, Self-help groups, Farmers

Approximate Costing

Brief Description : Chunks (Wadian), a traditional savoury food is usually legume-based and are more popular in northern India. Chunks are prepared from a thick, spiced batter, which is formed into balls of varying sizes (15 - 40g), and then dried. After drying, the chunks may be fried and eaten as a savoury snack, or may be added to other Indian dishes of rice, vegetables and pulses. Traditionally, drying of these chunks is practiced under the sun. It has many disadvantages. Hot air drying is an alternative method that decreases drying time and improves the quality of the dried product. Okra is the by-product of soy milk and tofu production. It contains protein and fiber which have value and which can be used in food products that meet market demands and opportunities. Moist okra from soymilk production has about 80% moisture. Wet okra has approximately the nutrient composition as water 81.6 gm, protein 3.2 gm (moisture basis), carbohydrate 12.5g, fiber 4.1g, calcium 80 mg, iron 1.4 mg, thiamine 0.02 mg, and riboflavin 0.02 mg. Process technology has been developed for chunks using soy-okra (a by-product of soymilk) partially replacing dhal (Pulses) to improve the nutritional quality and utilization of fresh okra (a byproduct from soymilk preparation). Incorporation of 20% fresh okra and hot air drying at 60° is recommended for the production of better quality dehydrated pulse (black gram & green gram) chunks.

Beneficiaries /End User : New upcoming entrepreneurs, soymilk and soypaneer processors, Self-help groups

Approximate Costing

Brief Description : Biscuits are ready to eat, convenient and inexpensive food product, containing digestive and dietary fibres of vital importance. Biscuits are a rich source of fat and carbohydrate, hence are energy giving food and they are also a good source of protein and minerals. Okra is the residue obtained from ground soybean after removing the water-extractable fraction used to produce tofu or soymilk. About 1.1 kg of fresh okra is produced from 1 kg of soybean processed for manufacturing of tofu. Okra contains protein and fibre which have value and which can be used in food products that meet market demands and opportunities. Okra is high in fibre. Moist okra from soymilk production has about 80% moisture. Wet okra has approximately the nutrient composition as water 81.6 g, protein 3.2 g (moisture basis), carbohydrate 12.5 g, fibre 4.1g, calcium 80 mg, iron 1.4 mg, thiamine 0.02 mg, and riboflavin 0.02 mg. The wet okra poses disposal problems in addition to existing pollution. It is a suitable dietary additive in biscuits and snacks because it reduces calorie intake and increases dietary fibre. Considering the barriers for the use of okra such as its rapid degradation, high cost of drying and alternative protein sources to okra, it is more feasible to use as such fresh okra obtained from soymilk production to make the product fibre rich. Hence, fresh okra is recommended for utilization in biscuit preparation. Incorporation of 20 % wet okra is recommended for the production of better quality fibre rich biscuits.

Beneficiaries /End User : New upcoming entrepreneurs, soymilk and soypaneer processors, Self-help groups

Approximate Costing

Brief Description : The snack food industry is experiencing extraordinary changes from the consumer's point of view. Consumers wants snacks that taste good and smell good, feel good, look good and in addition, nutritionally superior and healthy. The extrusion cooking process is high temperature short time process in which moist, soft grain is fed into the extruder where the desired temperature and pressure are obtained over the required period of residence time. Extrusion cooking is used worldwide for the production of expanded snack foods, modified starches, Ready- to- Eat cereals, baby foods and pasta. This technology has many distinct advantages like versatility, low cost, better product quality and no process effluents. The residue left after the water extractable fraction is utilized to produce soy milk and tofu is called okra (soymilk residue). About 1.1 kg of fresh okra is produced from 1 kg of soybean processed for tofu. Huge quantities of okra are produced during the production of soymilk and soypaneer. It is rich in moisture, fiber and carbohydrates. Considering the barriers for the use of okra such as its rapid degradation, high cost of drying and alternative protein sources to okra, it is more feasible to use as such fresh okra obtained from soymilk production to make the product fibre rich. Hence, fresh okra is recommended for utilization in RTE extruded snack preparation. Incorporation of 30% wet okra in rice-maize (20:80) proportion is recommended for the production of better quality fibre rich RTE extruded snacks

Beneficiaries /End User : New upcoming entrepreneurs, soymilk and soypaneer processors, Self-help groups

Approximate Costing

Brief Description : Noni (Morindacitrifolia L.) fruit contains more than 200 nutraceuticals and commercially available for consumption in the form of food supplement. Technologies has been developed to enhance the consumer acceptability of Noni in the form of pure juice, RTS beverages, toffees and fortified biscuits, bars, and cookies to utilize it as a novel food ingredient.

Beneficiaries /End User : Consumers (for health concern), entrepreneurs, farmers

Approximate Costing

Brief Description : Area under turmeric cultivation is tremendously increased. Processing facilities for turmeric should be strengthened without any constraints.

Process for turmeric processing :

Turmeric

Harvested after 9 Months

Harvested after 9 Months

Washing

Washing

Boiling/Curing

Boiling/Curing

DryingPolishing

DryingPolishing

Dried polished rhizomes

Dried polished rhizomes

Grinding in impact Pulverizer

Grinding in impact Pulverizer

Turmeric powder.

Turmeric powder.

Machineries forturmeric processing plant : Washer, Curing/Boiling, steam operated turmeric cooker /blancher to save energy, labour, time and also to improve the quality of rhizomes, Drying: Sun drying is recommended in month of April - May or can be used mechanical drying, Polishing : Drum polisher of different capacities up to 10 qt/batch with abrasion techniques, Impact Pulverizer : One step grinding process to have fine turmeric powder.

Beneficiaries /End User : Turmeric growers, Agricultural entrepreneurs, food industrialists.

Approximate Costing

Brief Description :

Turmeric (Curcuma longa) has innumerable health benefits. It can be put in the cooking recipes like curries, salads, salad dressings etc. Turmeric pickle is a potent relish that adds spice, pungency and tang to the turmeric. Apart from contributing certain desirable flavour characteristics to the turmeric, pickling also prolongs the availability period of it by processing at a relatively low cost.

The fresh turmeric pickle prepared with 15 per cent peeled ginger shreds and 20 per cent lemon juice was found to be highly overall acceptable and this formed the basis for standardization of recipe for fresh turmeric pickle keeping the other ingredients constants.A good quality of turmeric pickle having nutraceutical value can be prepared from by addition of 15 per cent ginger and 20 percent lemon juice in the recipe improved the organoleptic quality of turmeric pickle.

Machineries forturmeric processing plant : Washer, Curing/Boiling, steam operated turmeric cooker /blancher to save energy, labour, time and also to improve the quality of rhizomes, Drying: Sun drying is recommended in month of April - May or can be used mechanical drying, Polishing : Drum polisher of different capacities up to 10 qt/batch with abrasion techniques, Impact Pulverizer : One step grinding process to have fine turmeric powder.

Beneficiaries /End User : Consumers (for health concern), Turmeric growers, entrepreneurs, Pickle manufacturers, self help groups.

Approximate cost of Unit Development

Brief Description : Karela is good source of alkaloids and highly beneficial for diabetics. It is suggested that 10-15ml of Karela juice should be consumed early morning to control blood sugar level. However, the excess bitter taste of Karela reduces it consumer acceptability. Technology has been developed to enhance the consumer acceptability of Karela juice by blending it with amla juice which reduces the bitterness perception and enhances the consumer acceptability of the product.

Beneficiaries /End User : Diabetic patients, entrepreneurs, Amla and Karela growers.

Approximate cost of Unit Development

Brief Description : Safflower [Carthamustinctorius (L.)] is grown mainly for getting high quality edible oil rich in polyunsaturated fatty acids. Safflower petals are very important as a source of medicinal preparations, natural food colour and dyes for colouring fabrics. The technology preparation of Safflower herbal Tea has been developed with incorporation of different herbal ingredients to enhance its taste and consumer acceptability.

Beneficiaries /End User : Consumers, safflower growers, entrepreneurs, self help groups.

Approximate cost of Unit Development

Brief Description :

Wheat grass juice is a powerful concentrated liquid. It has twice the amount of vitamin A as carrot and higher vitamin C then oranges. It contains B complex vitamins as well as calcium, phosphorus, magnesium, sodium, potassium in a balanced ration. It is also source of complete protein.

Technology for development of wheat grass juice has been developed with optimum nutrients optimum nutrient

Beneficiaries /End User : Consumers, farmers, self-help group, entrepreneurs, diabetic patients, pregnant women, patient with imbalance blood pressure.

Approximate cost of Unit Development

Brief Description :

Apron is designed with long sleeves to prevent the body from direct exposure to sunlight as well as to prevent the skin from scratching while moving the field. A bag is attached to the apron for easily storing the collected cotton up to 5 kg. Useful even in vegetable and sugarcane harvesting. Reduction of cardiac cost of work is about 10%.

Measurements of Apron :

Measurements of bag :

Width : 100cm (with gathers) Length - 58cm

Acceptability of apron for cotton picking under the intervention program

| Factors assessed during intervention | Maximum attainable scores | Attained score | % of attained over maximum attainable | Remarks |

|---|---|---|---|---|

| Bio-medical/stress factor | 60 | 47.76 | 79.6 | Acceptable |

| Work out put | 15 | 12.26 | 81.73 | Highly acceptable |

| Tool factor | 15 | 13.2 | 88.0 | Highly acceptable |

| Field acceptability | 25 | 28.45 | 73.8 | Highly acceptable |

| Overall acceptability | 115 | 91.67 | 79.71 | Acceptable |

Beneficiaries /End User : Farm women, men and entrepreneurs

Approximate production cost

Brief Description :

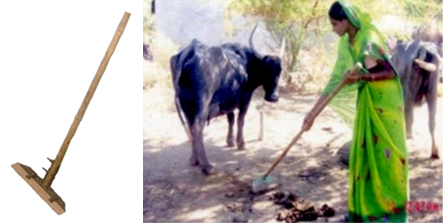

The Gopal Khore with long handle is developed for removing dung underneath animals. Drudgery of the worker and dung collection time is reduced by 50 percent. It is light and easy to handle, carry and store, can be easily developed by local fabricator. Dung collection is also possible on uneven surfaces with the help of Gopal khore.

Measurements of Gopal khore :

Beneficiaries /End User : Women and men workers in animal husbandry, entrepreneurs

Approximate production cost

Brief Description :

It is useful in all the places where organic dust and noise pollution is found such as flour & chilly pounding mill, bakery units, seed processing plant, wood cutting workshops, winnowing operations in farm, railway godown and industries. Partial noise and dust control ,conversation is possible because of mouth slit, comfortable breathing, easy to wear & wash, design of the mask is acceptable socially, low cost, easily made by local tailor with locally available material.

Measurements of of Noise and Dust Controlling Mask :

Beneficiaries /End User : Flour mill workers, entrepreneurs

Approximate production cost

Brief Description :

Useful for milking activity. It reduces stress and strain of milk workers. It helps to avoid spilling of milk. It helps in reducing physiological cost of work and body discomfort ratings (32%). It is mobile and simple. It can be made easily by local fabricators. Useful on uneven surfaces and for any type of containers. Easy to handle, carry and store.

Measurements

| Measurements | Milking stand | Milking stool |

|---|---|---|

| Height | 30 cm | 17 cm |

| Width | 40 cm | 39 cm |

| Upper diameter | 27 cm | -- |

| Lower diameter | 23 cm | -- |

| Legs with wheels | 3 No | 3 No |

| Leg Length | 12 cm | 12 cm |

| Legs with wheels | 3 No | 3 No |

| Leg Length | 12 cm | 12 cm |

| Overall acceptability | 115 | 91.67 |

Beneficiaries /End User : Women and men dairy workers, entrepreneurs

Approximate production cost

Brief Description :

It is useful in Soybean cutting, collecting and bundling and threshing soybean harvest. Ergonomic assessment report revealed that, it has multiple benefits with respect to physiological cost of work, health hazards and work output.

Measurements of mittens :

Material - Jeans cloth - 0.5 m, Length of the mitten - 58 cm, Width of the mitten - 17 cm, Palm length- 21 cm, Palm Girth - 35 cm, Wrist girth - 26 cm, Arm girth - 30cm, Length of the wrist belt - 27 cm.

| Name of the activity | Parameters for observation | Traditional method | Improved method | Percentage change due to technology | 't' test |

|---|---|---|---|---|---|

| Cutting soybean plants with sickle | Work done / unit time (sq. mt/ 30 min ) | 164.9±48.4 | 192.6±60.9 | 16.8 | NS |

| Collecting and Bundling of soybean plants | Work done / unit time (Kg/ 30 min ) | 120 | 150 | 25 | -- |

| Upper diameter | Drudgery score | 3.73 ± 0.59 | 1.93 ±0.45 | 48 | 10** |

| Lower diameter | Drudgery score | 4.4 ± 0.82 | 2.33 ±0.60 | 47 | 8.07** |

| Threshing | Drudgery score | 4.33 ± 0.61 | 2.63 ±0.73 | 39.3 | 7.08** |

Beneficiaries /End User : Female and male farm workers, entrepreneurs

Approximate production cost

Brief Description : Fertilizer application is one of the most arduous jobs in agriculture activities. This activity is performed manually in three different ways depending upon type of crop and stage of growth of crop. Agricultural labourers perceived physical and chemical hazards while performing fertilizer broadcasting. Hence, considering their specific problems, bag was designed, developed ergonomically tested for seed drill, spreading and ring methods. Work output was measured in terms of unit time/labourer / acre area under fertilizer application. It has multiple benefits with respect to physiological cost of work, health hazards and work output. Easy to wear. Useful for even carrying seeds in seed drill method and as a saplings carrier while transplanting.

Beneficiaries /End User : Women and men farmers, entrepreneurs

Approximate production cost

Brief Description :

The long handle of Trishul weeder facilitates the weeding by giving pressure by both the hands and it eliminates postural stress by reducing angle of deviation. Trishul weeder covers double area due to blades provided at it's both sides. Useful for manual weeding & fruit harvesting. It is light in weight

and easy to operate. It helps to improve the work posture of the worker from sitting to standing. The working efficiency increases because weeder has two blades. Long handle of the weeder is helpful for removing weed from field where height of the weed exceeds 5 ft., as it gives protection from insects bite like snake and scorpion. The blade has sharpness at both sides hence; it helps to cut the fruits and branches of trees.

Measurements of Trishul weeder :

Beneficiaries /End User : Women and men farm workers, entrepreneurs

Approximate production cost

Brief Description :

Ergonomic assessment of mittens revealed that physiological cost of work is reduced by 40 to 50 percent, body discomfort and health hazards were reduced significantly when okra and brinjal harvesting was performed manually by using mittens and apron. Use of okra and brinjal mittens increased work output by 9 to12 percent.

Work output while harvesting of okra and brinjals with traditional and improved method

| Parameters for observation | Traditional method | Improved method | Percentage change due to technology |

|---|---|---|---|

| A) Okra | |||

| Pace of work (hr/100kg) | 3.05 | 2.22 | 27.21 |

| Work done / unit time (sq mt/ hr) | 4.35 | 4.87 | 11.95 |

| Drudgery score | 8.66 | 5.26 | 39.26 |

| B) Brinjals | |||

| Pace of work (hr/100kg) | 15.29 | 12.85 | 15.96 |

| Work done / unit time (sq mt/ hr) | 8.68 | 9.46 | 8.98 |

| Drudgery score | 3.73 | 1.93 | 48.25 |

Beneficiaries /End User : Women and men farmers, entrepreneurs

Approximate production cost

Brief Description :

This child educational material is useful for developing recognition, word formation and reading skills in young children. Children enjoy identifying and building words.

Beneficiaries /End User : Pre-Primary and Primary School students, families, teachers and entrepreneurs

Approximate production cost

Brief Description :Soyane are prepared form soybean by using following steps.

| Ingredients | Quantity | Nutritive Value per 100g | Quantity |

|---|---|---|---|

| Soybean | 1 kg | Energy (Kcal) | 432 |

| Salt | 15g | Protein ( g) | 43 |

| Turmeric | 10g | Calcium (mg) | 240 |

| -- | -- | Iron (mg) 10 | 10 |

Beneficiaries /End User : Children & people of all age groups, entrepreneurs

Approximate production cost

Shelf life period : 3 Months

Brief Description :Soya poha laddu are prepared by using following steps.

| Ingredients | Amount | Nutritive Value per 100g | |

|---|---|---|---|

| Bengal gram dhal four | 10 | Energy (Kcal) | 510 |

| Soybean flour | 20 | Protein ( g) | 14 |

| Rice flakes | 10 | Calcium (mg) | 65 |

| Sugar | 25 | Iron (mg) 10 | 5.5 |

| Groundnut powder | 10 | ||

| Fat | 20 | ||

Beneficiaries /End User : Children, all age group people, particularly underweight people, entrepreneurs

Approximate production cost

Shelf life period : 1 Months

Brief Description : Nutricookies are prepared by using following steps.

| Ingredients | Amount (g) | Nutritive Value per 100g | |

|---|---|---|---|

| Refined wheat flour | 17 | Energy (Kcal) | 482 |

| Soy product (DOC) | 17 | Protein ( g) | 21 |

| Sugar | 25 | Calcium (mg) | 290 |

| Fat | 25 | Iron (mg) 10 | 2 |

| Skimmed milk powder | 10 | ||

| Roasted Bengal gram | 05 | ||

| Baking powder | 1.25 | ||

Beneficiaries /End User : Underweight person, preschool children, adolescents, pregnant and lactating women, old person, entrepreneurs

Approximate production cost

Shelf life period : 4 Months

Brief Description : Nutricookies are prepared by using following steps.

| Ingredients | Amount (g) | Nutritive Value per 100g | |

|---|---|---|---|

| Bajara | 10 | Energy (Kcal) | 317 |

| Jowar | 10 | Protein ( g) | 18 |

| Ragi | 09 | Calcium (mg) | 1433 |

| Rajkeera | 09 | Iron (mg) 10 | 6.5 |

| Red Chillies | 02 | ||

| Turmeric | 02 | ||

| Garlic Powder | 10 | ||

| Gingelly seed | 11 | ||

| Cumin seed | 07 | ||

| Coriander leaves fresh | 10 | ||

| Salt | 02 | ||

| Deoiled soya meal | 10 | ||

| Drumstick leaves powder | 04 | ||

| Cauliflower leaves powder | 04 | ||

Beneficiaries /End User : All age groups, entrepreneurs

Approximate production cost

Shelf life period : 10 Months

Brief Description : Nutricookies are prepared by using following steps.

| Ingredients | Amount (g) | Nutritive Value per 100g | |

|---|---|---|---|

| Rajkeera leaves powder | 30 | Energy (Kcal) | 105 |

| Amla jam | 30 | Iron (mg) 10 | 31 |

| Sugar | 10 | ||

| Ginger juice | 5ml | ||

| Lime juice | 5ml | ||

Beneficiaries /End User : Anaemic children and Adolescents, entrepreneurs

Approximate production cost

Shelf life period : 2 Months

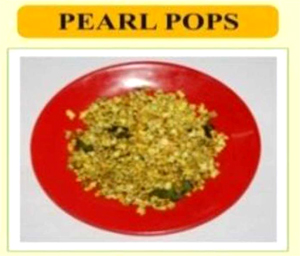

Brief Description : Pearl Pops are prepared by using following steps.

| Ingredients | Amount (g) | Nutritive Value per 100g | |

|---|---|---|---|

| Bajra pop | 60 | Energy (Kcal) | 155 |

| Puffed bengal gram dhal | 26 | Protein (g) | 13 |

| Cumin seed | 03 | Calcium (mg) | 132 |

| Turmeric powder | 04 | Iron (mg) | 19 |

| Rajgira leaves powder | 03 | ||

| Mango powder | 04 | ||

Beneficiaries /End User : Children, adolescent girls, entrepreneurs

Approximate production cost

Shelf life period : 2 Months

Brief Description : Mix Pulse Sev is prepared by using following steps.

| Ingredients | Amount (g) | Nutritive Value per 100g | |

|---|---|---|---|

| Green gram dhal flour | 12 | Energy (Kcal) | 514 |

| Soyabean flour | 20 | Protein (g) | 28 |

| Bengal gram Dhal | 05 | Calcium (mg) | 128 |

| Black gram Dhal | 03 | ||

| Oil | 10 | ||

Beneficiaries /End User : Children, adolescent girls, entrepreneurs

Approximate production cost

Shelf life period : 2 Months

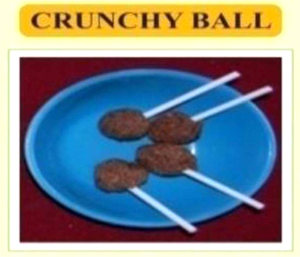

Brief Description : Crunchy Ball are prepared by using following steps.

| Ingredients | Amount (g) | Nutritive Value per 100g | |

|---|---|---|---|

| Sesamum | 10 | Energy (Kcal) | |

| Garden cress seed powder | 10 | Protein (g) | 8.31 |

| Rajkeera seed powder | 20 | Calcium (mg) | 340 |

| Mango powder | 05 | Iron (mg) | 16.10 |

| Skimmed milk powder | 05 | ||

| Sugar | 50 | ||

Beneficiaries /End User : Children, adolescent girls, entrepreneurs

Approximate production cost

Shelf life period : 2 Months

Brief Description : Nutri Grans is prepared by using following steps.

| Ingredients | Amount (g) | Nutritive Value per 100g | |

|---|---|---|---|

| Sesamum | 10 | Energy (Kcal) | |

| Garden cress seed powder | 12 | Protein (g) | 11.82 |

| Rajkeera seed powder | 10 | Calcium (mg) | 420 |

| Roasted Bengal gram flour | 05 | Iron (mg) | 16.60 |

| Coco powder | to taste | - | - |

| Skimmed milk powder | 13 | ||

| Jaggery | 50 | ||

Beneficiaries /End User : Children, adolescent girls, entrepreneurs

Approximate production cost

Shelf life period : 2 Months

Brief Description :Arm & leg fractured women in stage of plaster are unable to dress up in normal style without help of others. Unavailability of special clothing in market for arm & leg fractured physically disabled women results in lot of problems and mental stress. Specially designed Punjabi Kameez & Salwar reduce their discomfort, mental stress, time in dressing up and are very safe. They are designed using poplin / cotton cloth, front full opening and press buttons for easy fastening. Kameez sleeve opening is provided from shoulder to wrist and Salwar leg opening is provided from waist to bottom & zipper fasteners

Beneficiaries /End User : Arm and leg fractured physically disabled women, entrepreneurs

Approximate production cost

Beneficiaries /End User : Farmers and gardeners, entrepreneurs

Approximate production cost

Brief Description :Pleurotus species of mushroom can be cultivated very easily on agro waste. It contents high amount protein, micro-nutrients and less sugars

Beneficiaries /End User : Farmers and house holders, entrepreneurs

Approximate production cost

Brief Description :Handicrafts are hand made products prepared from raw indigenous material using traditional artistic tools or even some simple machinery in its designing / innovation. Products are catchy, cost effective objects of gift and decorative value. A value addition is upto 30.00% which cocoons are non reelable, are disposed off to spun silk industries at a very low rate. However, it is estimated that these cut cocoon byproducts could lead to a value addition upto 30.00% in mulberry post cocoon sector if utilized skillfully with effective management in cocoon crafting, besides, raw silk reeling from good cocoons.

Approximate production cost

Brief Description :

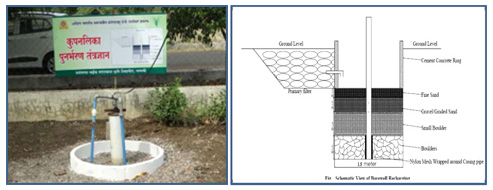

Groundwater is the most important natural resource. Over three fourths of food grains production coming from the irrigated lands is contributed by lands irrigated by groundwater. The dependence on ground water is increasing for agriculture. Large-scale exploitation of groundwater and negligible recharging has created water havoc in bore wellfed areas. Bore wells are getting dry causing acute shortage of irrigation and drinking water supply. Groundwater levels had reached alarming levels early this year itself. It is a economically viable and adoptable technology to cope with drought situation.

This technology had proven its significance in relation to increase in ground water levels and can create the source for supplemental irrigation to Kharif as well as rabi crop for assured food grain production.

Beneficiaries /End User : Suitable to all

The youth can be effectively trained with respect to planning, construction and implementation of the technology on large scale.